- No.1 Minfeng Rd., Jingbin lnd. Park, Wuqing District, Tianjin, China

- sales@worldhoists.com

- +86 4006-311-058

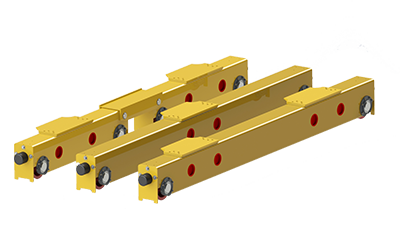

WORLDHOISTS’s?end carriages?feature a modular, direct-drive design, offering a compact structure and high transmission efficiency. Our crane end carriage provides a module joint design that fits with any building clearance, which flexibly adapts to various factory conditions and effectively reduces the need for building height, saving construction costs for customers.

-Diverse options: gantry crane end carriage, bridge crane end carriage,overhead crane end carriage etc.

-Flexible joint, smoothly running

-Compact design, Integrated motor + brake + gearbox

Choosing the WORLDHOISTS end carriages, designed and built with the expertise of leading end carriage manufacturers. We?provide?partners?with an efficient, stable, and flexible solution, helping them achieve optimal lifting experiences.

Modular and Flexible Design

The modular structure allows the end carriage of crane?to realize?quick installation and support both bridge and suspended crane configurations, ensuring adaptability to different working environments.

Compact and Efficient

The compact design reduces space requirements while enhancing transmission efficiency and lowering overall energy consumption.

Smooth and Stable Operation

The Articulated connection of end carriage crane components ensures smooth operation and prevents issues caused by uneven wheel pressure.

Versatile Connection Options

The crane end carriage offers multiple connection methods, suitable for different types of factory structures, meeting personalized needs and optimizing space utilization.

High-Quality Wheel Materials:

Ductile Iron Wheels (GGG70): Excellent self-lubricating properties reduce rail wear and extend service life.

Alloy Forged Wheels (42CrMo): Our end carriages?are made from high-strength materials, specifically designed for heavy-duty applications, ?ensuring long-term stability and reliable operation.

Enhanced Safety

Our crane end trucks are equipped with buffers to enhance safety and reliability.

Wide Type Options

WORLDHOISTS is a leading global end truck company that offers a wide range of?crane end trucks?products including overhead crane, gantry crane and bridge crane end trucks?to meet diverse needs of partners from various countries.

Below are the key specifications of our end carriages. All dimensions, weights, and performance data can be customized to suit particular site or load requirements. If you still have some problems, you can contact us for detailed drawings or project specific data at any time.

As a specialized end truck company,WORLDHOISTS focuses on delivering lifting solutions that combine structural flexibility and operational reliability.

The end carriages support multiple connection types with the main girder including top, middle, or side mounting. This flexibility allows easy adaptation to different building structures and helps reduce the overall building height.

The end truck is equipped with guide rollers to correct wheel deviation and reduce rail wear. Flat wheels eliminate the need for floor grooves, enhancing ground safety and enabling the smooth movement of other workshop equipment or logistics.

WORLDHOISTS’s?flexible end carriages are?designed with structural adaptability to ensure even wheel load distribution during operation. This reduces stress on the runway beam and minimizes the risk of uneven support or “three-leg” situations. The flexible connection enables the system to?self-adjust under varying loads, thereby improving overall stability and service life.

In contrast, traditional rigid end carriages?often result in concentrated wheel pressure. This can lead to unbalanced load distribution, overloading of individual wheels, and increased wear on runway beams, especially in cases of misalignment or uneven ground.